The Lean Six Sigma certification helps in validating professionals who are skilled in identifying risks errors or defects in. Six Sigma is mentioned in the PMBOK Guide and included in the PMP Exam Content Outline so you will see questions on this topic on your exam.

Lean Six Sigma Dan Peluang Pertumbuhan Bisnis Shift Indonesia

Six Sigma is a data-based methodology to improve performance by reducing variability.

Six sigma what is it. The method uses a data-driven review to limit mistakes or defects in a corporate or business. LSL and USL stand for Lower Specification Limit and Upper Specification Limit respectively. Lean Six Sigma is a method that relies on a collaborative team effort to improve performance by systematically removing waste and reducing variation.

The technique aims to produce products that are virtually defect-free Antony and Banuelas 2002. What Is Six Sigma. It offers statistical methods that reduce variance and help identify the root causes of errors for more effective and efficient processes.

Six Sigma 6σ is a set of tools and techniques developed by Motorola engineer Bill Smith for process improvements. A sigma is a measure of standard deviation abbreviated as small s or the Greek letter σ. The key goal of Six Sigma is to streamline business processes by decreasing defects variations and wastes in a product or service at the same time improving employee morale and quality of products.

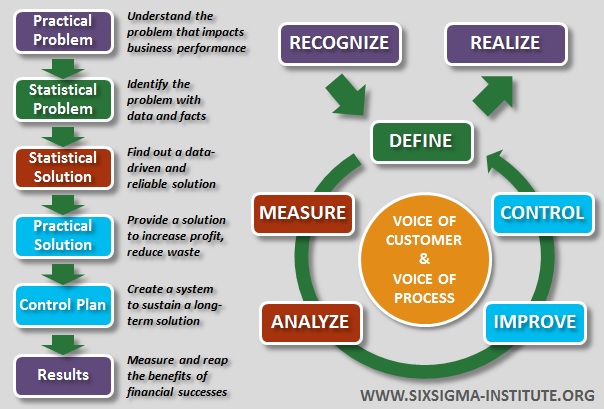

Six Sigma is a quality management methodology used to reduce defects and maintain consistency in products. Lean Six Sigma is one of the most powerful problem-solving and continuous improvement methodologies because it identifies the characteristics of the real problem. Six Sigma is a data-driven methodology that provides tools and techniques to define and evaluate each step of a process.

The philosophy behind Six Sigma is to identify removeimprove the processes that cause defects in manufacturing or business processes. In other words it is a methodology to achieve 34 defects per million opportunities. It requires thorough understanding of product and process knowledge and is completely driven by customer expectations.

Six Sigma stands for 6 standard deviations 6σ between avarage and acceptable limits. Specification Limits are derived from the customer requirements and they specify the minimum and maximum acceptable limits of. Something that is within -6s Six Sigma from the centerline of a control chart was created by.

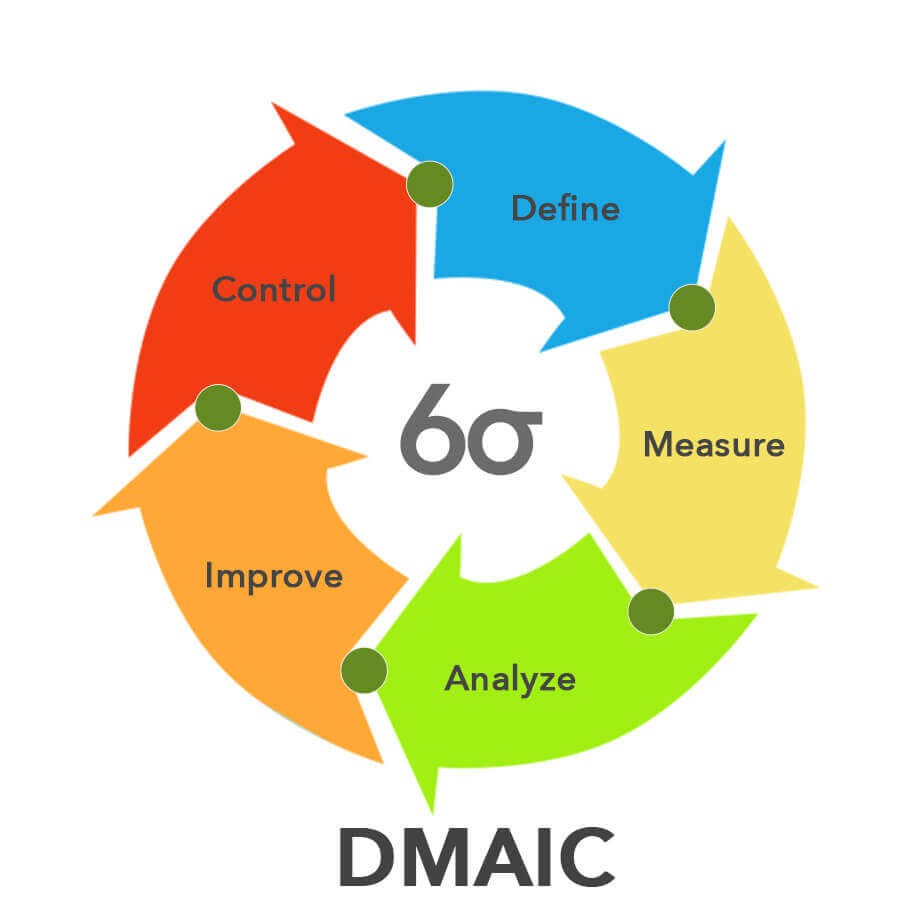

It provides methods to improve efficiencies in a business structure improve the quality of the process and increase the bottom-line profit. Six Sigma is a set of data-driven quality control techniques that aims to improve business processes by reducing the likelihood of defects and reducing the variations in processes. It drives towards six standard deviations between the mean and the nearest specification limitation.

Six Sigma provides qualitative tools to improve the capability of business processes. Six Sigma mostly measures quality of manufacturing output but also quality of products and services. Six Sigma is a set of tools and techniques used by companies to improve production processes eliminate defects and guarantee quality.

Six Sigma is a quality-control methodology developed in 1986 by Motorola Inc. Six Sigma is a disciplined data-driven approach or methodology to project management that eliminates defects in any process. It is a data-driven approach that uses a statistical methodology for eliminating defects.

Some methodologies start with the assumption that every problem has a unique or special cause and if that cause can be identified and eliminated or controlled the problem goes away. It can also be used to bring breakthrough improvements. Six Sigma is a set of management tools and techniques designed to improve business by reducing the likelihood of error.

Six Sigma Definition Six Sigma is a method of comparing organisation process performance with critical customer needs ensuring that business outputs its products and services are consistently designed to exact customer requirements. Six Sigma is a disciplined data-driven approach and methodology for eliminating defects driving toward six standard deviations between the mean and the nearest specification limit in any process -- from manufacturing to transactional and from product to service. Six Sigma derives from statistical process modeling in manufacturing.

What Is Lean Six Sigma Lean Six Sigma Groep

What Is Lean Six Sigma Lean Six Sigma Groep

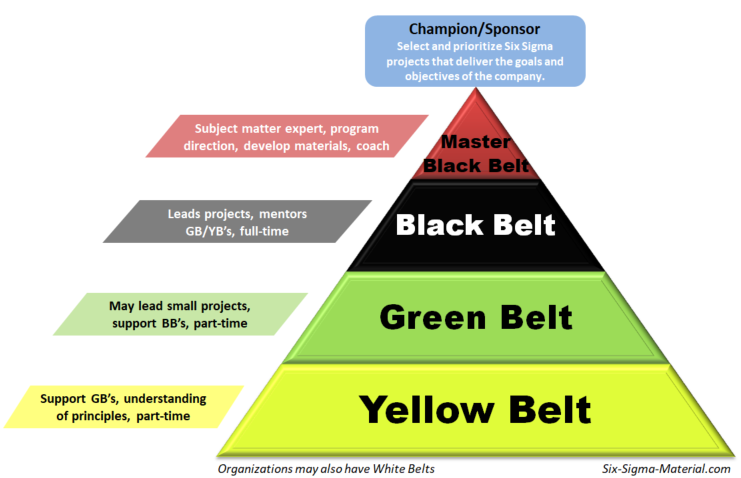

Six Sigma Material Training Courses Calculators Certification

Six Sigma Material Training Courses Calculators Certification

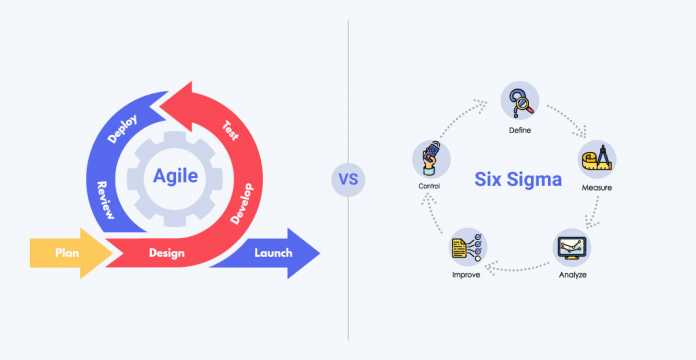

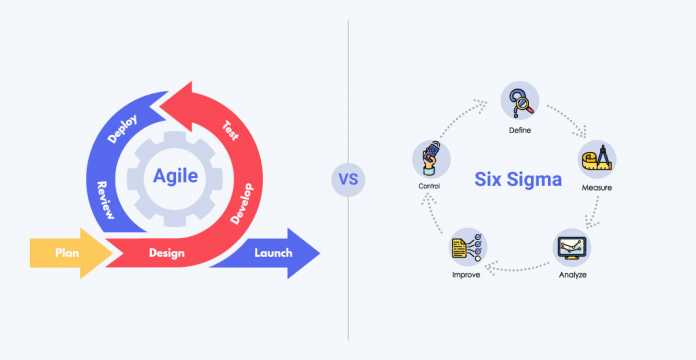

Agile Vs Six Sigma A Brief Comparison Invensislearning

Agile Vs Six Sigma A Brief Comparison Invensislearning

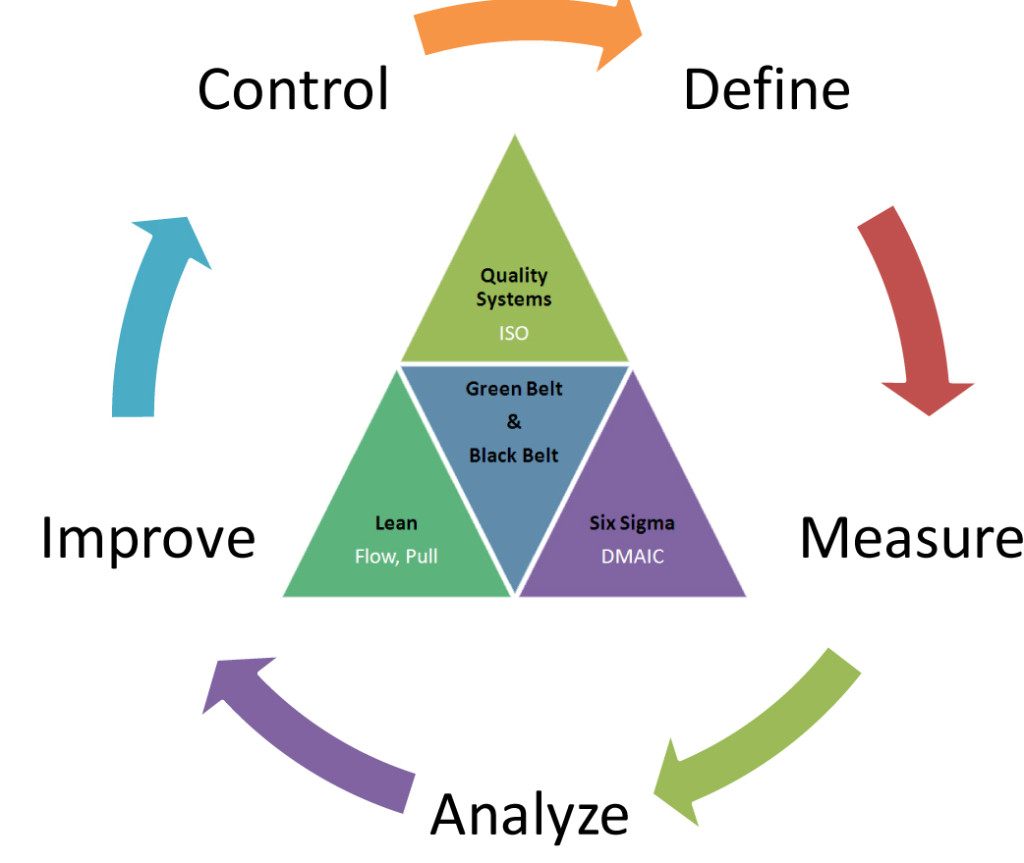

Lean Six Sigma People And Organisations

Lean Six Sigma People And Organisations

Six Sigma And Business Analytics Lean Six Sigma Analytics

Six Sigma And Business Analytics Lean Six Sigma Analytics

Six Sigma Adalah Metodologi Yang Penting Dalam Manajemen Kualitas Accurate Online

Six Sigma Adalah Metodologi Yang Penting Dalam Manajemen Kualitas Accurate Online

Lean Certification Lean Six Sigma Certificates Online Sdsu Global Campus

Lean Certification Lean Six Sigma Certificates Online Sdsu Global Campus

Pengertian Six Sigma Dan Tahapan Dmaic Ilmu Manajemen Industri

Pengertian Six Sigma Dan Tahapan Dmaic Ilmu Manajemen Industri

What Is Six Sigma And Why Is It Important Workzone

What Is Six Sigma And Why Is It Important Workzone

Six Sigma Overview Principles And Methodology

Six Sigma Overview Principles And Methodology

Using Six Sigma For Successful Project Management Infinity

Using Six Sigma For Successful Project Management Infinity

What Is Six Sigma International Six Sigma Institute

What Is Six Sigma International Six Sigma Institute

Back To Basics Six Sigma 2018 01 01 Quality Magazine

Back To Basics Six Sigma 2018 01 01 Quality Magazine

Apa Itu Six Sigma Definisi Implementasi Dan Tahapan Dmaic

Apa Itu Six Sigma Definisi Implementasi Dan Tahapan Dmaic

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.