While they may work full-time on a complete business process they will only devote 20-50 of their time to the project itself. In more detail Six Sigma Green Belt typically works part-time on Six Sigma projects.

All About Six Sigma Certifications Smartsheet

All About Six Sigma Certifications Smartsheet

These people conduct projects and implement improvements.

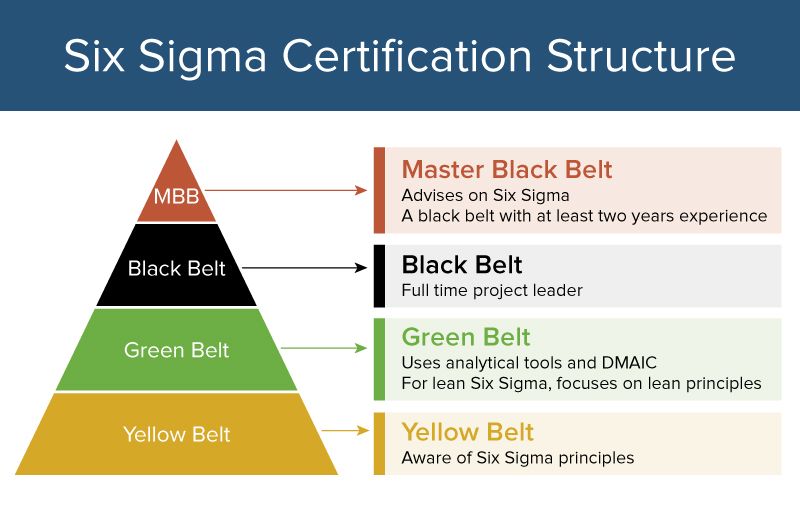

Lean six sigma levels. Six Sigma certification is divided into four different levels. People work with teams on problem-solving projects. Acts as an organizations Six Sigma technologist.

By obtaining this Lean Six Sigma credential they will have an edge over their peers and colleagues and there is a possibility to gain first preference by the organization when it comes to promotion. Early Success The initial projects are yielding results and early successes are being achieved. The focus is on applying Lean Six Sigma to lead and deliver an.

This means a six sigma process produces 34 defects per million opportunities or less as a result. These professionals are entitled to various color belts like yellow green black belt and master black belt. The aim of Six Sigma is to make a process effective with - 9999996 defect-free.

In most instances there are four different Lean Six Sigma Certification levels. However I will be. The Six Sigma training course is divided into four levels or belts These levels are consecutive with higher belts or levels requiring more understanding and skill than the lower belts.

10 25 of work time on process improvement activities. Launch This is the starting point wherein an initial few visionaries in the organization launch Six Sigma training is initiated and projects are begun. Green Belt training can take between 4 and 6 days and covers more of the tools and techniques than Yellow Belt training.

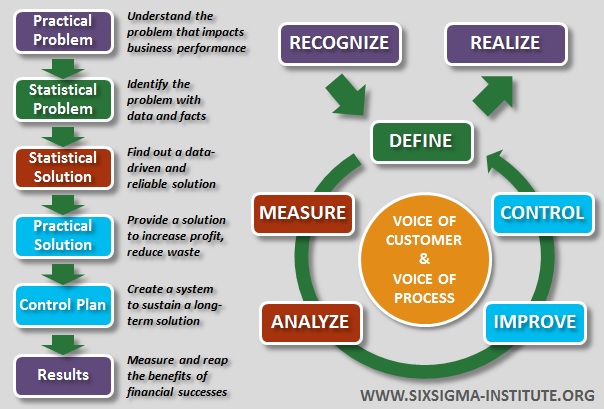

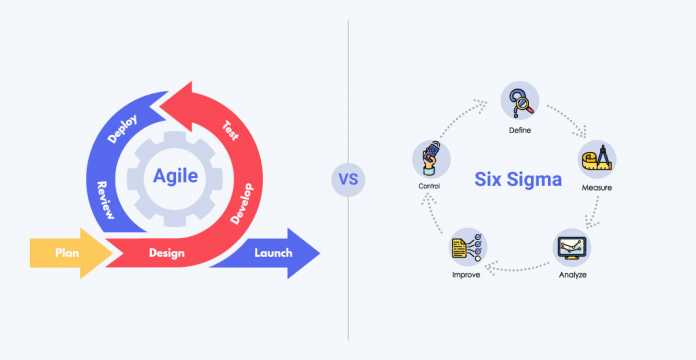

The participant is required to understand the basic Six Sigma concepts. At the project level there are master black belts black belts green belts yellow belts and white belts. Six Sigma is a structured problem-solving methodology.

Six Sigma Green Belts The first certification level you will experience the greatest reward at is achieving a Green Belts. Green Belt Lean Six Sigma belt levels explained. Secondly there are Green and Black belt certifications that consist of an exam as well as a practical assessment.

4 6 days of training. Six Sigma Certification Levels. These levels are referred as belts and these.

Six Sigma Levels. Any newcomer can join. Focuses on applying Lean Six Sigma to lead and deliver improvement projects.

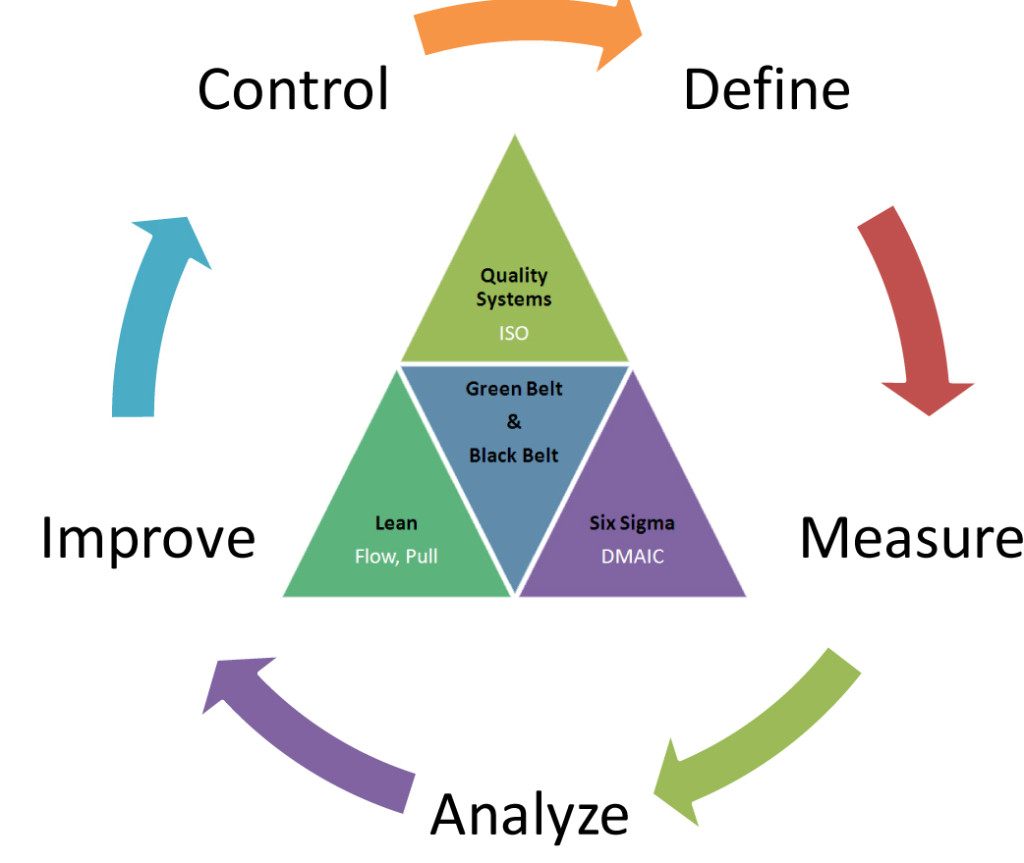

Problem-solving in Six Sigma is done using the DMAIC framework. Lean Six-Sigma Belts Lean professionals can be seen at various levels with different roles in the organization. These levels are referred to as belts and these belts are awarded to those individuals who are in a hierarchical format.

Trains and coaches Black Belts and Green Belts. Functions more at the Six Sigma program level by developing key metrics and the strategic direction. These belts differentiate the roles based on skillset and experience level.

This certification level requires professionals to attend a full course covering the Six Sigma methods and Lean concepts plus tutorials on their practical applications. This is the simplest stage where. Lean Six Sigma has adopted the roles from the Motorola Six Sigma methodology which borrow the naming convention of the progression of mastery used within martial arts.

A Lean Six Sigma Green Belt is the second official certification level for LSS professionals. Some organizations have their own levels and definitions of mastery. What are the Lean Six Sigma Certification Levels.

Scale and Replication The early success has led to other parts of the organization buying in to Six. The Six Sigma training levels conform to specified training requirements education criteria job standards and eligibility. The five levels are.

Six Sigma certification is split into four different levels. Six Sigma belts increase in order of yellow belt certification green belt certification black belt certification and champion certification. Firstly there are Yellow and Orange belt options that involve a multiple-choice exam.