Six Sigma is a data-based methodology to improve performance by reducing variability. Mura Mura is a Japanese word for inconsistency.

What Is Six Sigma International Six Sigma Institute

What Is Six Sigma International Six Sigma Institute

Muri Muri is a Japanese word that means to overly work hard.

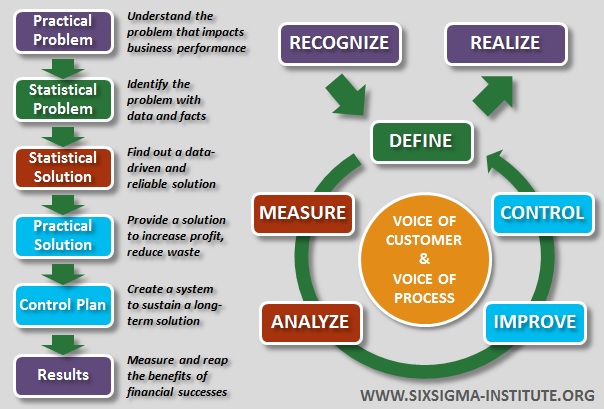

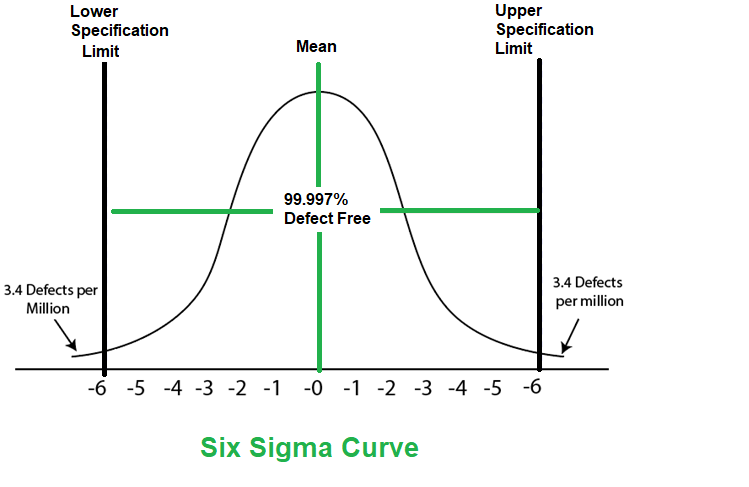

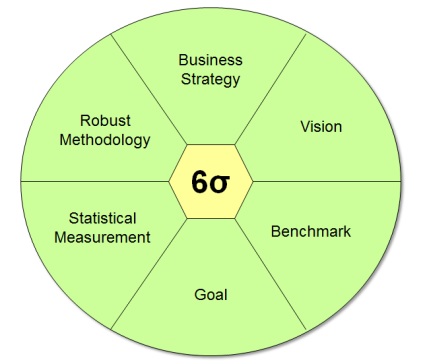

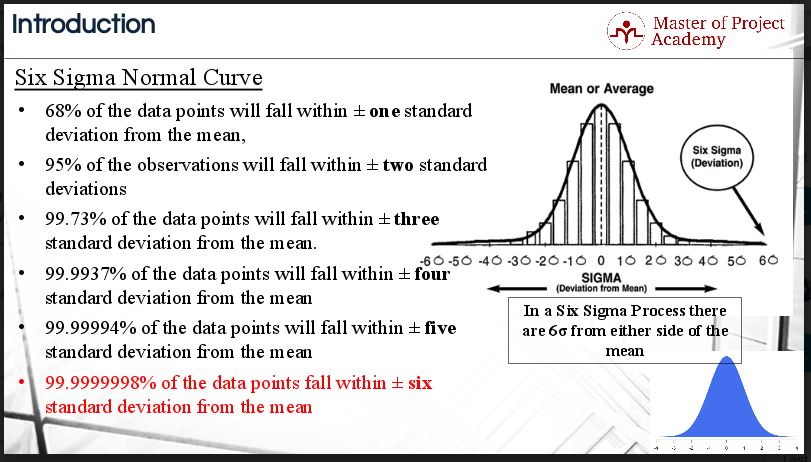

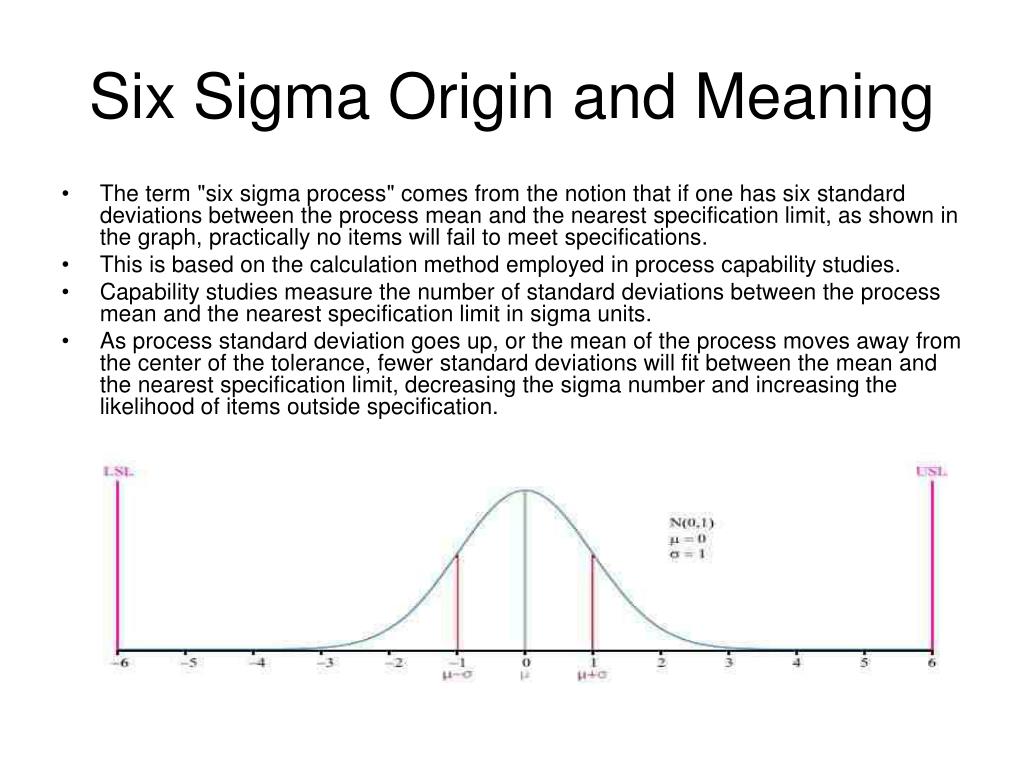

Six sigma meaning. In other words it is a methodology to achieve 34 defects per million opportunities. They ensure at a high level that projects succeed add value and fit within the organizational plan. Six Sigma is a disciplined data-driven approach and methodology for eliminating defects driving toward six standard deviations between the mean and the nearest specification limit in any process -- from manufacturing to transactional and from product to.

It requires thorough understanding of product and process knowledge and is completely driven by customer expectations. Translate the companys vision mission goals and metrics to create an organizational deployment plan and identify individual projects. Six Sigma is a quality-control methodology developed in 1986 by Motorola Inc.

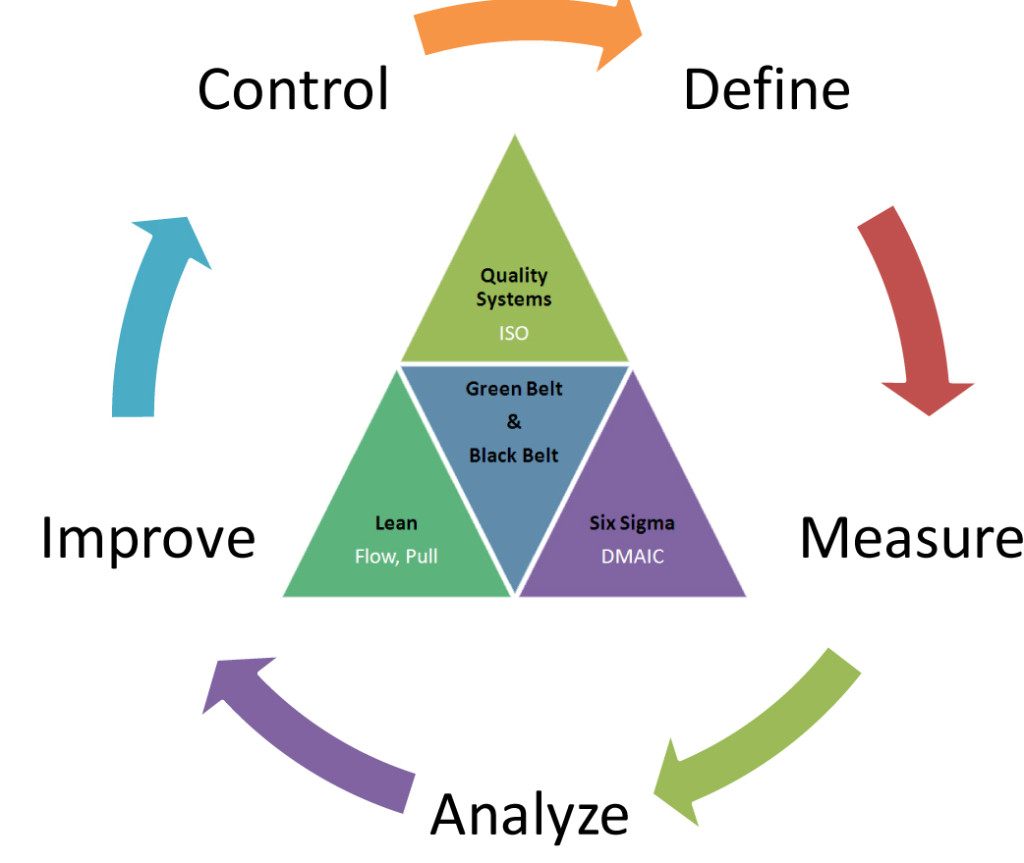

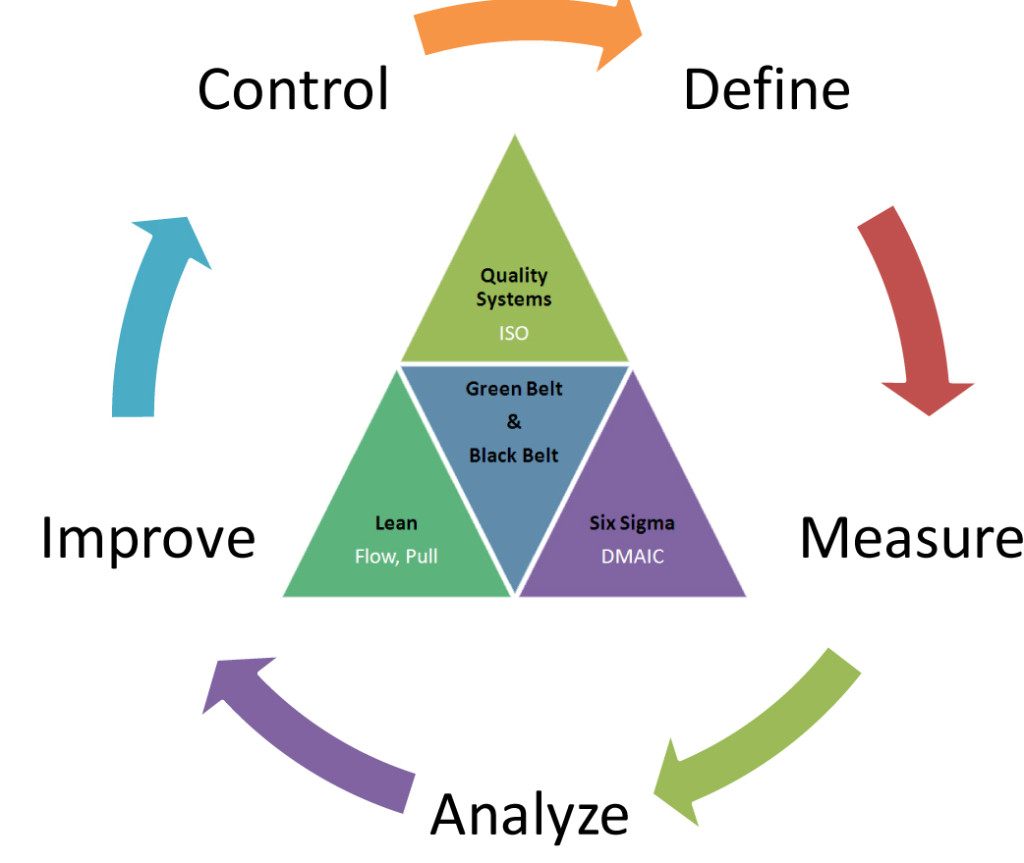

Which is a type of waste. Six Sigma is a set of management tools and techniques designed to improve business by reducing the likelihood of error. Lean Six Sigma is a process improvement methodology designed to eliminate problems remove waste and inefficiency and improve working conditions to provide a better response to customers needs.

Lean six-sigma is well defined as a process improvement methodology that is mainly used to remove waste inefficiency eliminate hindrances and provide better customer requirements. It has now become an industry. It provides methods to improve efficiencies in a business structure improve the quality of the process and increase the bottom-line profit.

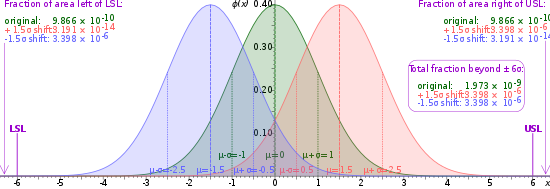

Which is a type of waste. The Sigma Level is one of the critical statistical terms of Six Sigma. Specification Limits are derived from the customer requirements and they specify the minimum and maximum acceptable limits of.

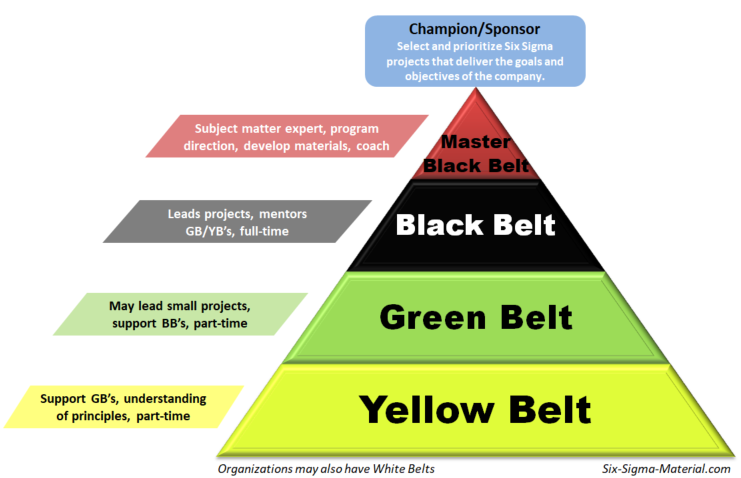

Muda is a key concept of the Toyota Production System. Six Sigma executives and champions set the direction for selecting and deploying projects. Six Sigma stands for 6 standard deviations 6σ between avarage and acceptable limits.

It combines tools and techniques methods and lean and six-sigma principles into a robust methodology to enhance organization performance. Six Sigma is a data-driven methodology that provides tools and techniques to define and evaluate each step of a process. A method for improving production processes so that the quality of products is nearly always.

It was originally developed as a management method to work faster with fewer mistakes. SIx Sigma is a data-driven approach to problem-solving and it is based on stats. It is a data-driven approach that uses a statistical methodology for eliminating defects.

LSL and USL stand for Lower Specification Limit and Upper Specification Limit respectively. Muda Muda is a Japanese word meaning waste.

Six Sigma Material Training Courses Calculators Certification

Six Sigma Material Training Courses Calculators Certification

Six Sigma Lean Manufacturing And Six Sigma Definitions

Six Sigma Lean Manufacturing And Six Sigma Definitions

Six Sigma Lean Manufacturing And Six Sigma Definitions

Six Sigma Lean Manufacturing And Six Sigma Definitions

Six Sigma In Software Engineering Geeksforgeeks

Six Sigma In Software Engineering Geeksforgeeks

What Is Six Sigma International Six Sigma Institute

What Is Six Sigma International Six Sigma Institute

How Do The Six Sigma Statistics Work

How Do The Six Sigma Statistics Work

Ppt Six Sigma Powerpoint Presentation Free Download Id 189945

Ppt Six Sigma Powerpoint Presentation Free Download Id 189945

What Is Six Sigma And Why Is It Important Workzone

What Is Six Sigma And Why Is It Important Workzone

What Is Lean Six Sigma What It Is Why It Matters How To Do It Right

What Is Lean Six Sigma What It Is Why It Matters How To Do It Right

Statistical Six Sigma Definition

Statistical Six Sigma Definition

Dmaic A Six Sigma Process Improvement Methodology

Dmaic A Six Sigma Process Improvement Methodology

/Lean_Six_Sigma_Structure_Pyramid-671e13ecc9e84e6e922d961234f57124.png)

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.